Search

Title: A Facile Strategy for the Development of Recyclable Multifunctional Liquid Crystal Polymers via Post-Polymerization Modification and Ring-Opening Metathesis Polymerization

Author: Xin Zhao, Yan Chen, Bo Peng, Jia Wei*, Yanlei Yu*

Journal: Angew. Chem. Int. Ed., 2023, 62(21), e202300699

Abstract:

Post-polymerization modification (PPM) offers a versatile approach for engineering multifunctional polymers, but this advantage has not been fully exploited to fabricate multifunctional liquid crystal polymers (LCPs). Here, we design a facile synthetic approach towards multifunctional LCP by combining the ring-opening metathesis polymerization (ROMP) with PPM, in which ROMP helps to prepare a reactive LCP precursor with high molecular weight, and PPM provides a facilitation to introduce functional groups into the precursor. Consequently, a photo- and humidity-responsive linear LCP (LLCP) is demonstrated to show the potential of this synthetic strategy to diversify functions of the LCPs. Under light irradiation and humidity changes, the deformation modes of the LLCP films are converted to complex shapes (bending, twisting, and curling). The obtained dual-responsive LLCP with high molecular weight possesses excellent processability and recyclability, making it possible to construct 3D shape actuators with programmable deformation behaviors under light/humidity.

Fulltext Link: https://onlinelibrary.wiley.com/doi/10.1002/anie.202300699

Article Express:

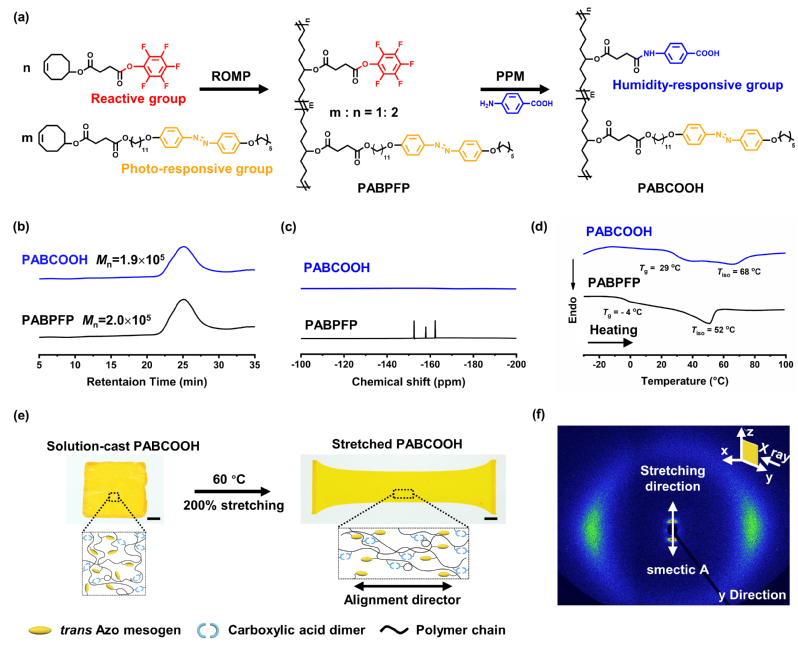

Herein, a facile synthetic approach by combining the ring-opening metathesis polymerization (ROMP) with Post-polymerization modification (PPM) has been developed to construct multifunctional LCPs (Fig. 1a), in which ROMP helps to prepare a reactive LCP precursor PABPFP with high molecular weight, good mechanical strength without crosslinking (Fig. 1b), and PPM provides a great facilitation to introduce functional groups. Based on this universal strategy, the team prepared a recyclable photo- and humidity-responsive linear LCP (PABCOOH) film with good liquid crystal orientation via mechanical hot-stretching (Fig. 1e, f).

Figure 1. a) Synthetic route of the reactive LCP precursor and the dual-responsive linear LCP. b-d) Gel Permeation Chromatography (GPC) curves, 19F NMR spectra and DSC curves of obtained linear LCPs. e) Schematic illustrations of the preparation of the stretched linear LCP film via hot-stretching process. f) 2D-XRD patterns of the linear LCP film with smectic A phase.

Under UV irradiation, the film bent along the direction of mesogen alignment due to the azobenzene molecules on the surface changed from trans isomers to cis isomers, and the cis isomers could return to trans isomers under visible light irradiation, making the film return to the flat state. In addition, carboxylic acid groups in the film mainly existed in the form of acidic dimers with hydrogen bonding interactions. After base treatment, the hydrogen bond network was destroyed and transformed into hygroscopic carboxylic salt. When the relative humidity of the environment increases, the film could absorb water and bend along the direction perpendicular to the mesogen alignment.

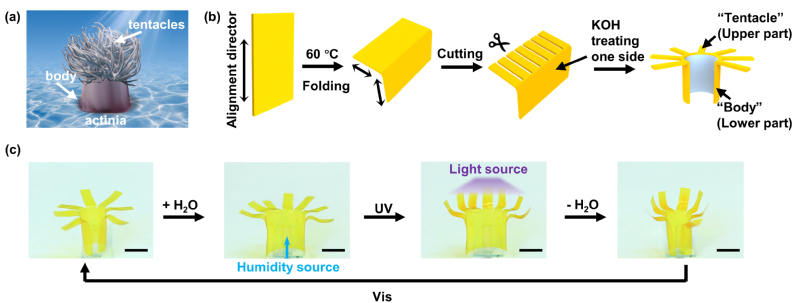

Thanks to the linear structure of the obtained LCP, three-dimensional shaping and recycling processes could be successfully realized. A bionic “actinia” three-dimensional actuator was then fabricated through folding and cutting, and it underwent anisotropic deformation behavior upon UV light irradiation and humidity changes. This synthetic strategy provides a facile platform for obtaining multi-stimuli responsive materials, and contributes to the construction of bionic three-dimensional actuators with multifunctional and controllable deformation direction, as well as its potential applications in intelligent soft robots and other fields.

Figure 2. a) Scheme of an actinia with the body and tentacles indicated by white arrows. b) Schematic illustration of fabricating process of an artificial actinia. c) The programmable deformation of an artificial actinia under different stimuli.

The research results were recently published as Hot Paper in Angew. Chem. Int. Ed., 2023, 62(21), e202300699.